Effects of Over-Firing and Chimney Fires on Stainless Steel Chimney Liners

Disclaimer

This document is intended for informational purposes only. Always consult local building codes, manufacturer-specific instructions, applicable industry standards (e.g., NFPA 211, UL 1777, UL 103HT, IRC), and certified chimney professionals before making final decisions on chimney liner selection, installation, inspection, or maintenance. Neither the author nor any referenced organization assumes liability for misuse of this information.

Table of Contents

Introduction

Purpose and Scope

Stainless steel chimney liners serve a critical role in safely venting combustion byproducts from residential and commercial heating appliances. They help prevent heat transfer to combustible materials, ensure optimal draft, and provide a corrosion-resistant conduit for flue gases. However, stainless steel—though robust—can fail under extreme conditions such as over-firing and chimney fires.

The purpose of this paper is to:

- Examine the metallurgical properties of stainless steel chimney liners (304, 316, and 316Ti) in high-temperature environments.

- Outline the risks and failure mechanisms associated with over-firing and chimney fires.

- Provide insight into regulatory codes (NFPA 211, UL 1777, UL 103HT, IRC) and professional best practices for installation, inspection, and maintenance.

Initial Overview

Modern stainless steel chimney liners protect the chimney structure from heat, corrosion, and combustion residues. Typical operating temperatures range from 300°F to 900°F, within which stainless steel performs reliably. However, user error or improper fuel selection can push flue temperatures above 1,000°F—often termed over-firing—leading to material warping or sensitization. More extreme events, such as a chimney fire (exceeding 2,000°F), can cause catastrophic liner failure.

Key Point: Passing a UL 1777 test at 2,100°F for 10 minutes does not guarantee a liner remains structurally sound after a real-world chimney fire. Post-fire inspections become essential.

Expanded Discussion

This paper explores:

- Metallurgical Properties: Common alloys (304, 316, 316Ti), heat behavior, oxidation scaling.

- Over-Firing: Causes, temperature thresholds, long-term structural impact.

- Chimney Fires: Extreme heat exposure, UL listings, and NFPA 211 requirements.

- Failure Modes: Warping, seam rupture, “invisible” damage.

- Standards & Testing: NFPA 211, UL 1777, UL 103HT, IRC.

- Maintenance: Inspections, cleaning, and homeowner education.

- Installation Best Practices: Correct alloy selection, insulation requirements, support, expansion allowances, and warranty considerations.

Metallurgical Properties of Stainless Steel Chimney Liners

Short Preamble

An understanding of stainless steel’s metallurgy under elevated temperatures is critical for assessing liner performance. This section introduces common alloys, their thermal behaviors, and the specific issues that arise when liners approach or exceed design temperature limits.

Common Alloys (304, 316, 316Ti)

-

304 & 316: Austenitic stainless steels with high chromium and nickel contents.

- Type 316 has ~2% molybdenum, improving resistance to acidic corrosion—key for coal or oil flues.

- 316Ti: Titanium-stabilized variant, minimizing sensitization by forming titanium carbides rather than chromium carbides. This enhances resistance to intergranular corrosion at higher temperatures.

Key Characteristics

- Corrosion Resistance: Derived from a passive chromium oxide layer that self-repairs at normal operating temperatures but can be damaged at extreme heat.

- Thermal Resistance: Can briefly endure 1,800–2,100°F, but prolonged exposure above ~1,000°F weakens mechanical strength significantly (AISI, 2019).

- Thermal Expansion: Rapid or uneven heating can cause warping or seam failure, especially in flexible liners.

- Work Hardening & Annealing: Repeated high-temperature cycles soften cold-worked steel, reducing structural rigidity.

High-Temperature Behavior

- Sensitization & Intergranular Corrosion: Occurs between ~800–1,500°F, forming chromium carbides at grain boundaries and depleting chromium in adjacent areas.

- Mechanical Strength Loss: By 1,000°F, Type 304 retains only ~22% of its tensile strength (AISI, 2019).

-

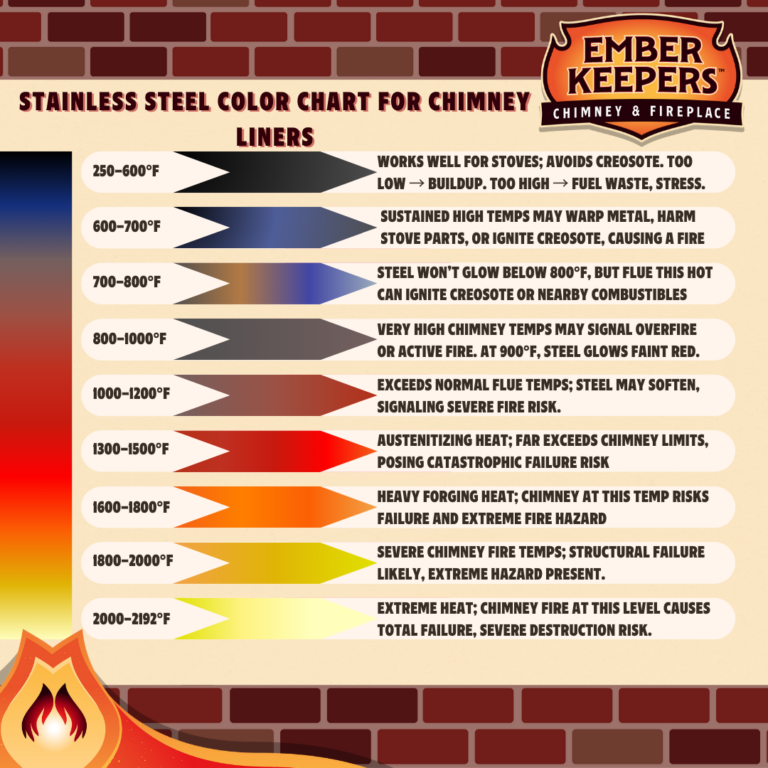

Oxidation & Scaling: Visible color changes:

- Straw-yellow (~600°F)

- Brown (~900°F)

- Blue/Purple (~1,100–1,200°F)

- Dull Gray (~1,400°F+)

Expanded Metallurgical Considerations

-

ASTM Tests:

- ASTM A240: Verifies mechanical/chemical composition.

- ASTM A262: Detects susceptibility to intergranular corrosion.

- Liner Gauge & Alloy Choice: Heavier-gauge steel or titanium-stabilized 316Ti can better withstand repeated heat cycles with less warping.

Section 2 Recap

- Stainless steel chimney liners rely on a protective oxide layer and austenitic microstructure.

- Elevated temperatures (>1,000°F) weaken the material’s tensile strength and can cause permanent metallurgical changes.

- Choosing the correct alloy and gauge helps mitigate failure risks in high-heat scenarios.

Over-Firing: Causes, Consequences, and Temperature Thresholds

Short Preamble

Causes of Over-Firing

- High Burn Rates (continuous high-output burning without reducing temperature).

- Excessive Draft (draft controls left fully open).

- Improper Fuel (burning resinous softwoods or extremely dry wood).

- Lack of Monitoring (no stovepipe thermometer to gauge flue temperature).

Effects of Over-Firing

- Warping & Structural Collapse: The steel weakens at sustained high temperatures, leading to permanent deformation.

- Microstructural Changes: Sensitization, oxidation scaling, and reduced corrosion resistance.

- Warranty Voids: Many manufacturers void warranties if liner damage indicates over-firing.

Detailed Temperature Thresholds

Section 3 Recap

- Over-firing is typically operator-driven, resulting from excessive draft or improper fueling.

- Even short exposures at 1,400–1,500°F can cause permanent damage.

- Manufacturers frequently deny warranty claims where over-firing is evident.

Impact of Chimney Fires on Stainless Steel Liners

Short Preamble

Chimney fires subject liners to sudden and intense heat spikes—often well above 2,000°F. This section highlights how such extreme temperatures degrade stainless steel.

Extreme Temperatures and Typical Damage

- Warping & Buckling: Rapid thermal expansion causes bulges and deformation.

- Seam Failure & Cracking: Joints can tear under intense heat.

- Oxidation & Discoloration: Thick oxide layers form, often in rainbow or dull gray patterns indicative of severe stress (CSIA, n.d.).

- Thermal Shock Damage: Rapid heating and cooling can introduce micro-cracks.

UL-Listed Liners in Chimney Fires

- UL 1777 and UL 103HT ensure containment of a short-duration chimney fire.

- NFPA 211 requires a Level 2 camera inspection post-fire to detect hidden failures.

- Even if a liner “passes” in containing the blaze, it may be irreparably damaged internally, requiring replacement.

Section 4 Recap

- Chimney fires far exceed normal operating temperatures, risking total liner failure.

- UL listings confirm short-term containment but do not guarantee post-fire usability.

- Always inspect liners and replace if structural compromise is suspected.

Failure Modes at Elevated Temperatures

Short Preamble

Thermal Warping and Buckling

- Stainless steel expands under heat; above ~1,000°F, yield strength plummets.

- Tall or unsupported liner sections—especially flexible liners—are prone to pronounced buckling.

Oxidation and Heat Discoloration

- Temper colors provide a clue about peak temperature exposure.

- Once heavy oxide layers flake off, the underlying metal is vulnerable to corrosion.

Seam or Joint Failures

- Welded or corrugated seams are mechanical weak points.

- Rapid expansion can tear or peel these seams, creating pathways for superheated gases to reach adjacent structures.

Structural Collapse or Melt-Through

- Though stainless steel has a melting point near 2,500°F (1,370°C), localized hot spots can degrade thinner gauges.

- Sustained exposure to ~2,100°F can lead to severe warping or partial burn-through.

“Invisible” Metallurgical Damage

- Sensitization: Formation of chromium carbides at grain boundaries.

- Annealing: Repeated extreme cycling softens cold-worked liners, reducing their load-bearing capacity.

Section 5 Recap

- Failure can manifest in warped or collapsed segments, torn seams, or color changes.

- Not all damage is immediately visible—microstructural degradation often requires camera or metallurgical inspection.

- Any suspected high-heat event necessitates thorough inspection to ensure long-term safety.

Direct Evidence and Real-World Case Studies

Short Preamble

Field Reports and Inspections

- Warped/Buckled Liners: Deformations commonly found in tall stacks.

- Seam Separation: Torn corrugations or welds.

- Discoloration: Especially at caps and top sections, hinting at extreme top-end temperatures.

Examples of Manufacturer Warranties and Breach Incidents

- 316L Liner Tear (Maine, 2019): A chimney fire caused multi-inch seam separation, leading to total liner replacement.

- Chronic Over-Firing: Homeowner burned ~900°F continuously for an entire season—liner ended bowed and discolored.

Forensic Indicators of Chimney Fires

- Puffy or Flaky Creosote: Ignited creosote expands and appears bubbled or charred.

- Rainbow-Hued Chimney Cap: Clear evidence of extremely high flue temperatures.

- Roaring Draft Sound: Often reported during a fire event.

Section 6 Recap

- Inspectors and sweeps rely on visual cues (buckling, discoloration) and creosote indicators.

- Manufacturer warranties typically exclude over-firing or fire damage, underscoring the importance of careful operation and thorough inspections.

Industry Standards, Codes, and Testing

Short Preamble

NFPA 211

- Annual Inspections: Level 1 if routine, Level 2 (with camera scoping) if over-firing or fire is suspected.

- Repair or Replacement: Any warping, seam failures, or cracks found means the liner must be replaced or repaired before further use.

UL 1777 and UL 103HT

- UL 1777: Chimney liners must sustain 2,100°F for 10 minutes without breach into surrounding structure.

- UL 103HT: Tests factory-built chimney systems in multiple 10-minute blasts at 2,100°F.

IRC and Other Local Codes

- IRC Recognition: UL 1777–listed liners are permitted in masonry chimneys if installed per instructions (including insulation if required).

- Local Building Authorities: Typically adopt NFPA 211, IRC guidelines, and require permits plus final inspections.

Section 7 Recap

- NFPA 211 enforces annual inspections and more rigorous checks post-incident.

- UL listings confirm fire-containment ability but do not guarantee post-fire liner usability.

- Local codes often mirror these national standards, mandating compliance and permits.

Testing Methodologies for Insulated vs. Uninsulated Liners

Short Preamble

UL 1777 Test Configuration

- Masonry chimney with the liner installed, including insulation if required.

- Thermocouples measure external wall temperatures during sequential burns up to 2,100°F.

- Passing Criterion: No structural breach, and outer chimney walls remain below ignition temperatures for surrounding materials.

ASTM Material Tests

- ASTM A240: Confirms mechanical and chemical properties.

- ASTM A262: Checks for susceptibility to intergranular corrosion.

- Others: Evaluate weld integrity, thickness uniformity, repeated heating/cooling tolerance.

Insulation Requirements

- Required if the liner fails UL 1777 in an uninsulated state.

- Insulation improves draft, protects adjacent combustibles, but can also retain heat in a chimney fire, possibly intensifying liner warping.

Section 8 Recap

- UL 1777 tests replicate real-world chimney fires but only for short durations.

- Insulation is vital for compliance in many solid-fuel applications.

- ASTM tests verify the baseline properties of stainless steel sheets and welds.

Preventative Measures and Maintenance

Short Preamble

Regular Chimney Cleaning

- Creosote should not exceed 1/8” buildup (CSIA, 2007).

- Frequent sweeping reduces the chance of chimney fires and high-heat stress on liners.

Annual Inspections (NFPA 211)

- Level 1: If no known issues exist.

- Level 2: If over-firing, chimney fire, or structural concerns are suspected.

- Early detection is crucial to avoid catastrophic failures.

Proper Burning Techniques

- Maintain flue temps in the 300–600°F range.

- Burn only seasoned wood (<20% moisture). Avoid resinous softwoods or chemically treated materials.

- Use a stovepipe thermometer to track temperature peaks.

Avoiding Thermal Shock

- Do not abruptly close the damper on a roaring fire.

- Never throw flammable liquids into stoves or fireplaces.

Spark Arrestors and Chimney Caps

- Prevent embers from escaping.

- Slow oxygen flow slightly during a chimney fire, possibly reducing peak temperatures.

- Clean regularly to ensure adequate airflow.

Timely Repairs

- Even minor seam cracks need immediate attention.

- Warped liners should be replaced to maintain efficiency and safety.

Education and Monitoring

- Teach homeowners the signs of a possible chimney fire (roaring draft, glowing stovepipe).

- Flue thermometers or digital monitors help operators keep temperatures in safe ranges.

Section 9 Recap

- Simple prevention (cleaning, safe burning practices, routine inspections) significantly reduces the risk of high-heat damage.

- Timely maintenance and repairs help avoid larger structural problems.

- Education is key: both professionals and homeowners must recognize early warning signs.

Industry Best Practices for Installation and Inspection

Short Preamble

Proper installation and thorough inspections can dramatically improve a liner’s longevity. This section highlights key considerations for professionals during and after installation.

Correct Alloy Selection and UL Listing

-

Match alloy to fuel type:

- 316 or 316Ti for wood, coal, oil.

- 304 for gas or non-acidic environments.

- Always verify UL 1777 or UL 103HT listing for the intended application.

Following Manufacturer Instructions

- Some UL-listed liners require insulation to maintain their listing status.

- Ignoring insulation can create unsafe conditions and void warranties.

Ensuring Structural Soundness

- Address crumbling mortar joints or protruding flue tiles before inserting a liner.

- Remove old, damaged clay tiles if necessary to accommodate the new system.

Support and Expansion Allowances

- Use top plates or support brackets to prevent liner sagging.

- Do not rigidly anchor both ends—allow room for thermal expansion.

Post-Installation Checks

- Camera Inspection: Ensure no kinks, tears, or seam separations.

- Documentation: Record liner model, size, and install details for future reference.

Warranty Considerations

-

Many “lifetime” warranties require:

- Annual inspections and cleaning.

- Proper installation per the manufacturer.

- No proven over-firing or chimney fire damage unless a post-fire inspection deems the liner structurally intact.

Section 10 Recap

- Proper alloy, insulation, and structural support are critical to performance and code compliance.

- Follow all manufacturer guidelines to ensure warranty coverage.

- Detailed post-installation records simplify future inspections and service.

Summary of Findings and Professional Recommendations

Short Preamble

Overall Findings

- Thermal Limits: Stainless steel performs well under normal flue temps (up to ~900°F) but weakens quickly above 1,000°F.

- Over-Firing Risks: Prolonged 800–900°F or spikes to ~1,400–1,500°F cause deformation, oxidation, and seam failure.

- Chimney Fires: Temperatures of ~2,100°F can lead to catastrophic liner failure, including warping, seam rupture, and possible burn-through.

- Code Compliance: NFPA 211, UL 1777/103HT, and IRC require proper liner installation and post-fire inspections.

Recommendations

-

Educate Homeowners

- Safe burning practices (seasoned wood, flue thermometers).

- Importance of routine cleaning and inspections.

-

Inspect After High-Heat Events

- Level 2 camera inspection whenever over-firing or a chimney fire is suspected.

- Replace liners showing warping, seam failure, or heavy oxidation.

-

Insulate When Required

- Follow UL 1777 listing—uninsulated liners in solid-fuel applications may violate code.

-

Consider Heavier-Gauge or 316Ti for High-Heat Use

- Improved resilience to frequent temperature cycling.

-

Document Everything

- Keep photographic evidence, temperature logs, and annual service records.

- Compliance with manufacturer instructions preserves warranty coverage.

Comprehensive Conclusion

-

Stainless steel chimney liners represent a robust and cost-effective solution for venting modern heating appliances. Under normal conditions—flue temperatures from 300°F to 900°F—they offer reliable corrosion resistance and structural stability. However, over-firing events (800–1,500°F) and chimney fires (often exceeding 2,000°F) expose liners to stress levels beyond their safe design thresholds. These conditions commonly lead to warping, seam rupture, oxidation scaling, and “invisible” metallurgical damage.

Although UL 1777 and UL 103HT certifications confirm the liner can contain a fire for a short period, they do not guarantee the liner will remain serviceable afterward. Consequently, NFPA 211 mandates a Level 2 camera inspection following any suspected chimney fire or overheat event.

Key Takeaways

- Prevention—through proper burning techniques, annual sweeping, and flue temperature monitoring—is the most effective strategy.

- Inspection—particularly post-fire or overheat—ensures continued safety.

- Installation and Maintenance—adherence to insulation requirements, manufacturer guidelines, and expansion allowances greatly reduces the risk of catastrophic liner failure.

Bibliography

American Iron and Steel Institute (AISI). (2019). Stainless Steels for High-Temperature Applications.

Chimney Safety Institute of America (CSIA). (2007). Chimney Fires: Causes, Effects & Evaluation.

Chimney Safety Institute of America (CSIA). (n.d.). Chimney Fire Safety Tips. Retrieved from csia.org (access may vary).

International Code Council (ICC). (2021). International Residential Code (IRC).

IRC Chapter 10 and 18. (n.d.). Building code references for masonry and venting systems.

NFPA 211. (1996). Standard for Chimneys, Fireplaces, Vents, and Solid Fuel–Burning Appliances.

NFPA 211. (2022). Standard for Chimneys, Fireplaces, Vents, and Solid Fuel–Burning Appliances.

NFPA 211 1996.pdf. (n.d.). Historical edition of NFPA 211 standard for chimney safety.

Underwriters Laboratories (UL). (2018). UL 103HT – Standard for Factory-Built Chimneys.

Underwriters Laboratories (UL). (2021). UL 1777 – Standard for Chimney Liners.

Ventis Chimney Liner Manual. (n.d.). Installation and Maintenance Instructions for Ventis-Forever Flex and ArmorFlex Liners.

White Paper on Chimney Fires. (2007). Chimney Fire Education and Research Task Force.

Ember Keepers—Stainless Steel Color Chart.png. (n.d.). User-provided heat discoloration chart for stainless liners.